Video

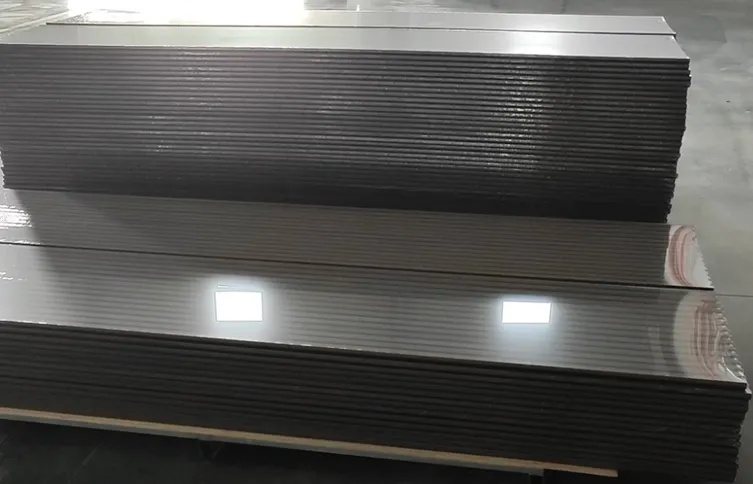

The workers are loading the polyester grille panels for the UK customer's order into the container. They carefully stack the panels to ensure stability and prevent damage during transit. The process is efficient, with each panel securely placed to maximize space and protect the product.

Grille acoustic panels are produced through a series of precise steps. Make the holes into a uniform pattern to form a grid design. These panels are often backed with sound-absorbing materials to enhance their acoustic performance. The panels are assembled with care, ensuring structural integrity and acoustic effectiveness. Quality checks are conducted to ensure each panel meets the required acoustic standards before packaging .